In the context of oversupply in the global panel industry, the pace of investment by panel manufacturers has slowed down significantly. Sharp's large-size panel production line in Japan has been shut down. This series of events has triggered in-depth discussions on the current situation and future direction of the panel industry.

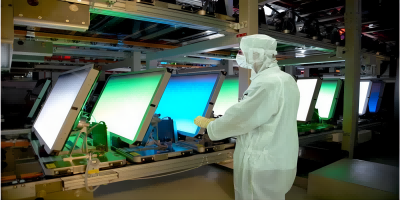

When US President Joe Biden attended the event of Microsoft's artificial intelligence data center being built in Virginia, he expressed his dissatisfaction with the investment under the "Made in America" policy of the Trump era. In particular, Foxconn's 10.5 generation LCD panel plant, which was originally planned to be built in Wisconsin, failed to materialize after several changes and scale adjustments. The original investment plan has shifted to the production of Netcom equipment for servers and cloud computing, reflecting changes in industry trends and the flexibility of enterprises to adjust.

In Japan, Sharp's Osaka Sakai plant is also facing a transformation. As the large-size panel business continues to lose money, Sharp plans to stop production in the third quarter of this year and transition to artificial intelligence AI data centers. This decision is an important step for Sharp to achieve the goal of asset-light, but also in the context of the global panel industry oversupply, the inevitable choice for enterprises to seek survival and development.

At the same time, Taiwan panel manufacturer AU Da is also actively adjusting the production structure. After the closure of the Singapore panel plant at the end of December 2023, AU began to adjust some of the panel production lines in Taiwan to meet the new market demand. This reflects the positive response strategy taken by Taiwan panel manufacturers in the face of industry oversupply pressure.

International Data Information Company (IDC) senior research analyst Chen Jianzhu pointed out that at this stage the panel industry oversupply, manufacturers more strictly control production to avoid price declines. He further analyzed that the LCD panel factory set up overseas faces the dilemma of lack of industrial settlements and high investment costs, which has led to the failure of many projects at the plant stage or the change of investment direction.

For Taiwan's LCD panel production line, Chen Jianzhu suggested that panel factories should be activated, such as transforming to produce a new generation of panel technology Micro LED panels, or putting in advanced semiconductor sealing and measuring processes. He stressed that Taiwan's panel factories need to transform, no longer limited to pure panel production, to adapt to industry changes and market demand.

Regarding Hon Hai's investments in the United States and Japan, Chen said these investments are affected by geopolitical risks. Hon Hai tried to reduce the risk by investing in the United States, but a lack of local component factory support led to a surge in production costs and eventually had to adjust the investment content. Investments in Japan are intended to diversify geopolitical risk, but Sharp's Sakai 10-generation line still faces competitive pressure from oversupply.

* Disclaimer: This article is from the Internet, if there is any dispute, please contact customer service.